Introduction

Peristaltic pumps have gained popularity across industries for their unique ability to transfer fluids with precision and minimal contamination. Whether you’re in the medical field, a laboratory, or a manufacturing plant, selecting the best peristaltic pump can make all the difference in efficiency and reliability.

What Are Peristaltic Pumps?

Definition and Functionality

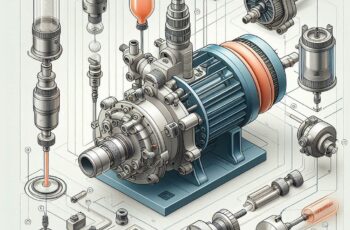

A peristaltic pump is a type of positive displacement pump that moves fluids through a flexible tube using a series of rollers or shoes. This action mimics peristalsis, the process by which food moves through the digestive tract.

Key Components

- Tubing: Flexible and durable, the tubing is critical for transferring fluids.

- Rotors: The rollers compress the tubing, creating the pumping action.

- Housing: Protects the components and provides structural integrity.

How Do Peristaltic Pumps Work?

Principle of Operation

The pump operates by compressing and releasing the flexible tube in a controlled manner. This creates a vacuum effect, drawing fluid into the tube and pushing it out the other side.

Advantages of Peristaltic Action

- Gentle handling of fluids

- Accurate dosing

- Reduced risk of contamination since fluids only contact the tubing

Applications of Peristaltic Pumps

Medical Industry

Used in dialysis machines and IV pumps, these pumps provide precise control critical for patient safety.

Laboratory Use

Ideal for chemical dosing and small-volume fluid transfers, peristaltic pumps ensure accuracy in experiments.

Industrial Applications

- Wastewater Treatment: Pumps handle abrasive and viscous fluids efficiently.

- Food and Beverage Processing: Maintain hygiene standards with food-safe tubing.

Features to Consider When Choosing a Peristaltic Pump

Flow Rate

Ensure the pump can handle the required fluid volume per minute for your application.

Pressure Handling Capacity

Choose a pump that matches the pressure requirements of your process.

Compatibility with Fluids

Check the tubing material’s compatibility with the fluids you plan to pump.

Maintenance Requirements

Opt for pumps that are easy to maintain, with accessible components.

Top 5 Best Peristaltic Pumps in 2025

Pump 1: XYZ Precision Pump

- Features advanced digital controls and exceptional accuracy.

Pump 2: FlexFlow Industrial Pump

- Designed for heavy-duty industrial use, handling abrasive fluids with ease.

Pump 3: MedFlow Mini Pump

- Compact and reliable, perfect for medical applications.

Pump 4: ChemDose Pro Pump

- Specially built for chemical handling, resistant to corrosion.

Pump 5: FoodFlex Hygienic Pump

- Made with FDA-approved materials, ideal for food and beverage industries.

Benefits of Using Peristaltic Pumps

Accurate Fluid Transfer

The design ensures precise dosing and flow control.

Easy Maintenance

Minimal moving parts mean fewer chances of mechanical failure.

Reduced Risk of Contamination

Since fluids only touch the tubing, there’s no risk of cross-contamination.

Maintenance Tips for Peristaltic Pumps

Regular Inspection

Check for wear and tear on tubing and rollers regularly.

Cleaning and Tubing Replacement

Clean the tubing after each use and replace it as needed to maintain performance.

Troubleshooting Common Issues

Identify and resolve issues like inconsistent flow rates or unusual noises promptly.

Conclusion

Peristaltic pumps offer a reliable and versatile solution for fluid transfer in various industries. By considering factors like flow rate, pressure handling, and maintenance, you can select the best pump for your needs.